Our Cimatron software allows for a seamless transition between electrode design, programing, and EDM. Customer data and lineup documents can be quickly reviewed from which we will strategize the full spectrum of the work at hand. Our many years of experience allows us to supply our customers with a fast response regarding problem areas, timing, and cost.

Our Cimatron software allows for a seamless transition between electrode design, programing, and EDM. Customer data and lineup documents can be quickly reviewed from which we will strategize the full spectrum of the work at hand. Our many years of experience allows us to supply our customers with a fast response regarding problem areas, timing, and cost.

ELECTRODE DESIGN

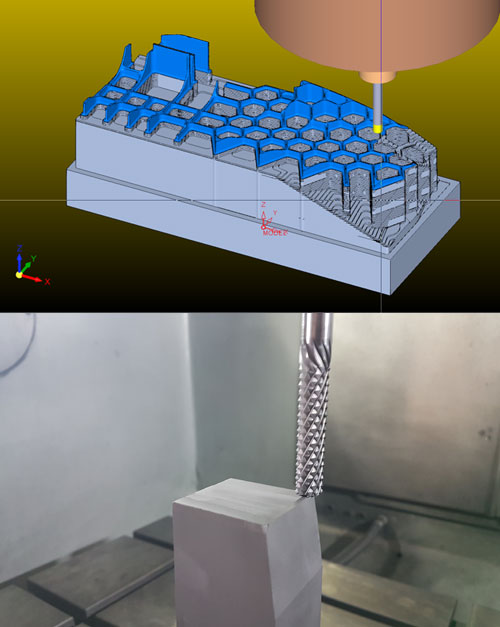

Cimatron allows our designers to quickly and efficiently map out and extract electrodes. With previously created templates, electrodes of similar size and topologies can be designed in seconds. We have created an in-house data base that includes every style of electrode holder in our inventory (3R-Erowa-Hirschmann) as well as machine layouts of all CNC Sinkers on our floor. A complete model of electrode-holder-machine can be generated and checked for areas of collision and violation.

ELECTRODE PROGRAMING AND MACHINING

Much like the design stage, reusable templates can be selected based on our milling strategies and electrode geometry. Colour coding is easily applied during design notifying the programmer of areas requiring specific attention like clearance and seal off. Unique electrodes such as speaker grilles and thin-walled rib clusters (mesh grilles) have special cutter path selections pre-made which can be duplicated from job to job without the inconvenience of reprogramming. Our Electrode Production Cell (EPC) has the capability to run 24hrs a day, 7 days a week. Consisting of two CNC mills and a 90 position interchangeable robot, we have the power to manufacture electrodes continuously without interruption.

EDM

The shop floor contains two Cimatron viewing stations allowing a paperless flow from electrode design to EDM. Our experienced operators and state of the art machine tools combine to form a team with unlimited capabilities. Thread, fine finish, and vector burning are only a few aspects of EDM that we are accustomed to on a daily basis. Through trial and testing, the full knowledge of our CNC sinker capabilities allows us to efficiently EDM all workpieces regardless of material, density, or texture. As with the Electrode Production Cell , our sinkers are outfitted with toolchangers allowing for uninterrupted machining while pre-programming to maximize machine run time.